transition from ductile to brittle temp impact test|ductile to brittle experiment : service A drop weight impact testing machine analyzes a material's ductile to brittle transition according to the puncture test method or tensile impact test procedure. This blog looks at how the latest drop weight impact . WEBshufflesex.com is not responsible for third party website content. If one of this file is your intelectual property (copyright infringement) or child pornography, illegal pornography / immature sounds, please contact us via email or submit a DMCA complaint . Arise Paechy, Ariase Peachy, Arise Peachy, Arisepeach, Arise Peachi, Arise Peach, .

{plog:ftitle_list}

Sabemos que os canais de atendimento ao consumidor e serviços de ouvidoria das empresas deveriam ser suficientes para o consumidor resolver todas . Ver mais

A drop weight impact testing machine analyzes a material's ductile to brittle transition according to the puncture test method or tensile impact test procedure. This blog looks at how the latest drop weight impact .

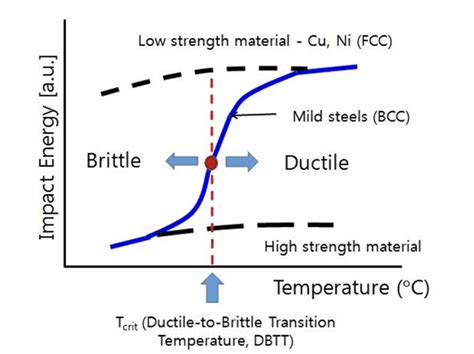

These materials show a transition from ductile to brittle behavior with temperature (Figure 2-2). This means that at low temperature the fracture energy is low. The mechanical behavior of .All tests were performed as instrumented impact tests, recording the force applied to the specimen during impact, at temperatures ranging from lower shelf conditions (fully brittle . However, for certain materials, at a specific temperature there exists a point of no-return where there is a transition in fracture behaviour from ductile to brittle failure. This is known as the Ductile to Brittle Transition .

The ductile-to-brittle transition (DBT) temperature is a dominant index of measuring the brittle transition tendency of bcc metals, which determines the cryogenic toughness of the materials .

The transition from high-temperature ductile to lower temperature brittle behavior below the DBTT is very clear. The coating process, phase distribution, composition, heat treatment .The ductile/brittle transition temperature for any given sample of steel is traditionally measured by breaking a notched bar in a pendulum-type impact tester and measuring the energy .The ductile/brittle transition temperature for any given sample of steel is traditionally measured by breaking a notched bar in a pendulum-type impact tester and measuring the energy .

Ductile-brittle transition temperature is the temperature at which metallic materials undergo transition from a ductile state to a brittle state. It is represented by T k, .Ductile–brittle Transition Temperature – Testing. The ductile-brittle transition temperature (DBTT) is the temperature at which the fracture energy passes below a predetermined value (e.g., 40 J for a standard Charpy impact .

The ductile-to-brittle transition temperature is the temperature at which the test specimen will start to become more brittle than ductile. From: A Quick Guide to Welding and Weld Inspection, 2009. About this page. Add to Mendeley Set alert. . In modeling a Charpy impact test, the first step is the comparison of the experimental and .

Ductile-brittle transition is mostly studied by impact tests. The name of Charpy Footnote 1 remains associated with impact testing on notched specimens. He published his first results in 1901 at a congress in Budapest, as well as in the Société des Ingénieurs civils de France (Charpy 1901).Originally this test was used mainly as a quality control test (see .the Charpy Test to explain the temperature transition from ductile to brittle fracture. Ductile to Brittle Transition Temperature (DBTT) is the minimum amount of energy that can be absorbed by a material before fracturing. When the temperature and energy data points are plotted, the transition temperature can be located when there is a stark . The ductile–brittle transition temperatures (DBTT) from the (corrected) test data are determined for the two materials based on the criterion of 20.4 J (15 ft-lb) absorbed energy.Fracture toughness values of the DP590 steel were also obtained through the correlation with the Charpy impact energy data. For many materials impact tests display a ductile-brittle transition when temperature is lowered. Analyses of the limit moment of notched test pieces and of the stress distribution are given .

• the relationship between different measures of ductile-to-brittle transition temperature; • comparisons between, and normalization of, characteristic instrumented forces obtained from different . the production of reference Charpy specimens for the indirect verification of impact testing machines in accordance with ASTM E23-12c: two .

ductile to brittle transition

The transition temperature is the temperature below which a material sample shows a rather brittle behaviour in the Charpy impact test and above the transition temperature a rather tough one! In comparison to materials with body-centered cubic lattice structures, the temperature has hardly any influence on the toughness for materials with face .

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. . The ductile-brittle transition temperature (DBTT) may be derived from the temperature where the energy needed to fracture the material .Ductile Brittle Transition Temperature Curve Source: ResearchGate Note: On the cooling of polymer, the DBTT may not correspond to the DBTT observed on heating of the polymer. a. Effect of temperature on amorphous polymers . It involves non-instrumented impact testing. ISO 6603-2 — It determines the puncture impact behavior of rigid plastics .to below the ductile to brittle transition temperature. This temperature is often the lowest temperature at which a structural engineering material can be considered useful. The transition temperature is also . The Charpy impact test is a relatively simple, qui ck and inexpensive method for testing the dynamic

2009. The aim of this study was evaluated the ductile-to-brittle transition temperature (DBTT) by five different methods: lateral expansion, shear fracture appearance, the average between lower and upper-shelf, load diagram and master curve using instrumented Charpy tests with total impact energy was 300 J and the impact velocity was 5.12 m/s.

When the same samples are subjected to the impact test at temperatures from high to low, the consumed impact energy (or impact toughness) will be from large to small, the number of crystalline fractures will be from less to more, and the plastic deformation will be from large to small, indicating that the material undergoes transition from a ductile state to a .Such a temperature is thus referred to as the brittle-ductile transition temperature or BDTT. Testing Methods. The Charpy Impact Test. The Charpy impact test has been used as a standard test to study the temperature-dependent BDT. The test was named after the French scientist Georges Charpy, who developed the test in 1905. This study addresses the correlation between the ductile-to-brittle transition temperature ranges of high strength 4140 steel obtained respectively from tensile tests under plane strain (PS .Charpy V-notch (CVN) impact test has been widely adopted to determine the DBT of various construction steels by the relationship between the absorbed energies and the impact temperatures [1, 2, 4, 8, 9], as shown in Fig. 1. In Fig. 1, there are three typical . Ductile–brittle transition temperature (DBTT) can be referred to as the .

The aim of this study was evaluated the ductile-to-brittle transition temperature (DBTT) by five different methods: lateral expansion, shear fracture appearance, the average between lower and upper-shelf, load diagram and master curve using instrumented Charpy tests with total impact energy was 300 J and the impact velocity was 5.12 m/s.The ductile-to-brittle transition temperature (DBTT) is the temperature range at which a material transitions from exhibiting ductile behavior, characterized by significant plastic deformation before fracture, to brittle behavior, where it fractures with little or no plastic deformation. Understanding DBTT is crucial as it affects the performance of materials under . The brittle-ductile transition and nonlinear deformation behaviors are the prominent characteristics of the rock. Rocks transition in failure mode from localized brittle fracture to non-localized .

This paper discusses the correlation between specimen dimensions and transition temperature. Notch toughness properties of Standard Charpy-V specimens are compared to samples with lower width (7.5 mm, 5 mm, 2.5 mm) and sub-size Charpy specimens with cross section 3×4.In this study transition curves are correlated with lateral ductile part of fracture . It is known that specimen size affects the ductile-brittle transition temperature in Charpy impact testing [5], and there is some evidence that sub-sized Charpy tests provide nonconservative .Influence of specimen dimensions on ductile-to-brittle transition temperature in Charpy impact test . Specimen Size on Charpy Impact Testing J. Nucl. Mat. 155(157) pp 662-667 [9] Lucon E . From the previous research, Lopez et al. explored the effect of samples dimensions on brittle to ductile transition temperature in impact test Charpy-v has been evaluated [7]. In recent years, the .

This work presents the Charpy energy values (CVN) in the ductile-to-brittle transition (DBT) temperature zone for different directions with respect to the longitudinal direction of API 5L X52 seamless pipeline steel. The material-processing directions were L-T, T-L, S-T, T-S, L-S, S-L, and 45°. At the same time, the temperature variation was –100, 0, 25, 50, .There are many ways to prevent or reduce the impact of hydrogen embrittlement in metals. . some metals can undergo a ductile-brittle transition which makes the material brittle and could lead to catastrophic failure during operation. This temperature is commonly called a ductile-brittle transition temperature or embrittlement temperature.Tensile test of an Al-Mg-Si alloy.The local necking and the cup and cone fracture surfaces are typical for ductile metals. This tensile test of a nodular cast iron demonstrates low ductility.. Ductility refers to the ability of a material to sustain significant plastic deformation before fracture. Plastic deformation is the permanent distortion of a material under applied stress, as opposed .Figure 1 (a) Charpy V-notch (CVN) impact energy versus temperature and the ductile-brittle transition temperature (DBTT); (b) a comparison of materials A to B. The ductile-brittle transition temperatures (DBTT) from the (corrected) test data were also determined for the two materials, based on the criterion of 20.4 J (15 ft-lb) absorbed energy .

ductile to brittle testing

webAtendimento Telefônico. Call Center 24h (Capitais): 4002.3633 ou 4020.3633. Call Center 24h (Pernambuco): 4002.2870. Call Center 24h (Interior e capitais): 0300 313 3633. Marcações de consultas e exames: 6h às 22h. SAC 24h (exclusivo para telefones fixos): 0800 280 9130. Ouvidoria (8h às 18h): 4020.9091.

transition from ductile to brittle temp impact test|ductile to brittle experiment